How To Install Blum Slides

How To Brand Easy DIY Drawers with Blum Undermount Slides // Home Bar Pt. 2

Learn how to build easy DIY drawers using pocket holes and plywood! Also, learn how to install Blum Tandem undermount soft close drawer slides.

Notation: the links beneath are Amazon affiliate links

Pin information technology!

Soft Close Drawer Slide Installation Process:

Step 1: Planning Out Spacing Of Each Drawer

I used ½" Maple plywood for the drawer sides and ¼" Maple plywood for the lesser and broke downwards the pieces for the sides on the table saw to get-go.

Earlier moving on, let's hop into SketchUp and so I tin can show you how these drawers need to be assembled to work with these Blum undermount hinges.

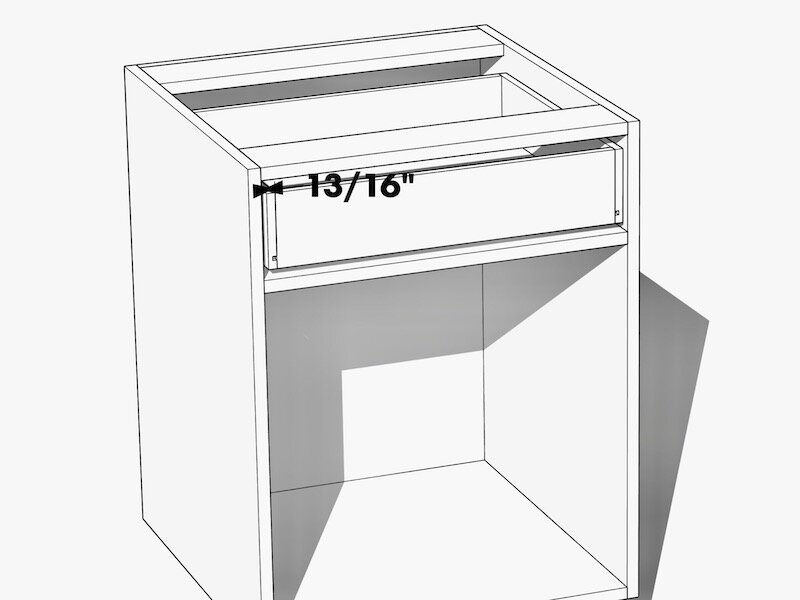

The inside faces of the drawers demand to be spaced thirteen/16" of an inch from the within of the cabinet. While this sounds like a pretty specific number, information technology'due south really pretty simple to work out the length of the front and dorsum of your drawer boxes.

Beginning, take the inside width of your cabinet, 22 ½" in my instance, then subtract 13/16" of an inch times 2, which is i ⅝". This left me with a measurement of xx ⅞", which is the length of the front and back panels on my drawer box.

The length of the sides is much easier, it just has to match the length of the drawer slides, 21" in my case.

The lesser of the drawer has to be inset in from the lesser edge of the drawer box ½", regardless of the thickness of your drawer bottom, and this provides clearance for the slides. To do this, I housed the bottom panel in a groove that was half the depth of the sides.

Finally, I needed to notch out the back of the drawer to provide clearance for the slides. This notch needed to be ½" tall by i ⅜" broad, and I needed to cut a notch on both sides of the dorsum.

That'south pretty much all of the details you lot'll need to build your drawer boxes, so let'south get back to the build.

Step 2: Material Preparation For Soft Close Drawers

As I mentioned, I needed to have the bottom housed in a groove, and information technology needed to exist ready in exactly ½" from the bottom edge of the drawer. I set up my blade to ¼", fix the argue of my table saw to ½", and then fabricated my outset pass on all of the drawer sides.

After making the commencement laissez passer, I moved the fence over a niggling less than ⅛", fabricated a cut, tested the fit on a piece of ¼" plywood, and so made a 2d pass on all of the boards. You want the fit to be tight, but not so tight that the drawers will be annoying to gather.

Side by side, I needed to notch out the backs of the drawer boxes to accept the undermount slides, and I did this at the bandsaw. I feel like this was i of the faster ways to do this, but there are plenty of options here. You could use a dado stack on the table saw, or I know my buddy Shaun Boyd, who has a great video on installing these undermount slides, uses a template and a flush trim scrap.

Anyway, as you'll see, I accidentally notched the fronts and backs of the drawer boxes, so I had to go back and recut the fronts, only eventually everything was notched out correctly and I could move on to assembling the drawer boxes.

Step 3: Drilling Pocket Holes In Drawer Box Parts

In one case again, I called on pocket holes for associates hither, which volition exist completely hidden in the finished drawer. Since I used ½" plywood, I swapped over to the Kreg Micro-Pocket guide, which drills smaller pocket holes which work better with thinner stock. You tin use the standard pocket hole jig, but I got a lot better results with this micro guide.

Once that was set up, I drilled pocket holes on each cease of the drawer fronts and backs.

Step 4: Drawer Bottoms and Assembly

Now that the drawer sides were to their final size, I could cut my drawer bottoms to size. Again, I used ¼" plywood here.

To assemble the drawers, I added a bead of Krazy Glue to the grooves and ends of the sides and then put the parts together. I and so clamped the drawer box together, used a mallet to make sure everything was flush, and so added the screws. I used ¾" screws here, which are the perfect size for this ½" material.

Subsequently adding the screws, I checked the drawer box for square, and also checked to see if the sides were bowed at all. This plywood was slightly warped equally I mentioned and, if there was any bow, I just added a clench to the middle until the bow was removed.

Step 5: Soft Close Drawer Slide Mounting

Side by side, I just repeated the procedure for the other four drawer boxes so I could get the Blum slide hardware installed.

This Blum system uses these ii clips at the forepart of the drawer boxes, which clip onto the slides. The orange levers allow you to easily add and remove the drawers and also provide some adjustment to the finished drawer.

To allow the drawer to have the slides, there are a few pretty specific holes yous need to drill. Starting time, this hole on the dorsum of the drawer accepts this pin on the back of the slides, which hooks into the drawer box and keeps information technology securely in identify.

To drill these holes, I used this crawly jig from Rockler, which is as well where I got these slides. The jig has metal bushings to guide the drill bits, which are also included with the jig, and the jig has a locator channel which allows you to easily gear up the stop block on the $.25.

Anyway, afterwards drilling the holes on the back of the drawer box, I used the aforementioned jig laid on its side to drill the pilot holes for the clips. These need to exist drilled at an bending, and this jig makes that super unproblematic.

I just repeated the process on the residual of the drawers and then I could motility on to installing the slides.

Once once more, I chosen on some other jig from Rockler, this undermount drawer slide jig, which made installing these slides super piece of cake. The jig sets the proper setback from the forepart border of your chiffonier and also holds the slide deeply in identify while giving y'all a nice clamping surface.

I also cutting some spacer strips out of flake plywood to aid brand sure everything was aligned, and these strips combined with the jig made this honestly the easiest drawer slide installation I've ever had.

I used a self-centering drill bit to drill the holes and so added screws.

In one case the slides were installed, I could install the drawer, which simply drops onto the slides and clips into place, and that was it. As y'all can see, these slides have an crawly soft shut action and the adaptability makes them pretty much foolproof.

Also, you can see just how hands you can remove the drawers past pressing the 2 clips. If you tin can't tell, I freaking love these slides and will be using them on basically every project I can in the future.

Anyhow, to install the rest of the slides, I would kickoff cut down my spacer strips at the miter saw and so just repeat the process. This went super quick and, once all 4 drawers were in, I could get this super satisfying shot closing all of the drawers.

Pace 6: Installing False Fronts To Soft Close Drawers

And with that, the drawers were built and installed, so I could motion on to calculation the faux fronts, which I covered in the previous bar build video, which I'll link here in case yous missed it.

Source: https://craftedworkshop.com/blog/how-to-make-easy-diy-drawers-blum-undermount-slides

Posted by: harrissirstion.blogspot.com

0 Response to "How To Install Blum Slides"

Post a Comment